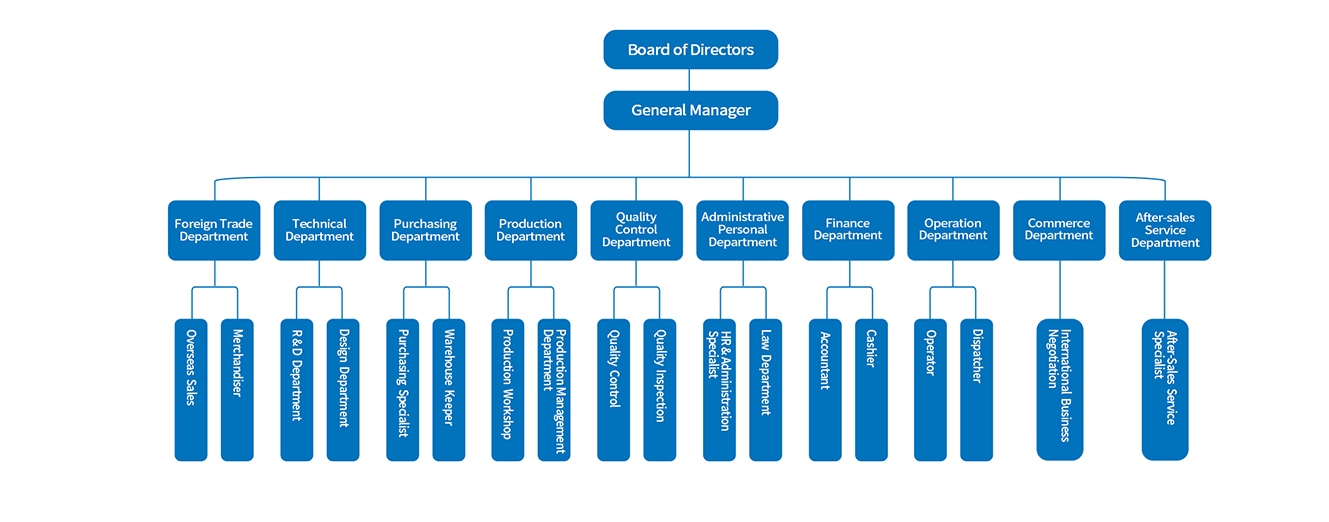

Yancheng Lianggong Formwork Co., Ltd., founded in 2010, is a leading manufacturer of formwork and scaffolding. Our main products are hydraulic auto-climbing formwork, cantilever climbing formwork, H20 timber beam formwork system, single-sided bracket, protection screen and unloading platform, table formwork, flex-slab formwork, trench box, plastic formwork, steel frame formwork, aluminum frame formwork, drophead slab formwork, customized steel formwork, tunnel formwork for housing, ring-lock scaffolding, etc.

Professional Consultancy Services:

Our sales department collaborates closely with the R&D team to provide tailored consultancy services.

We offer formwork recommendations based on clients' structural diagrams, quality and pricing consultations, delivery, and packaging advice.

Technical Planning Expertise:

Our technicians design and modify Auto-CAD drawings according to clients' requirements.

From preliminary drawing creation to final quotation confirmation, we ensure a streamlined and efficient design process.

Comprehensive Technical Support:

We provide all necessary shop and assembly drawings before product delivery.

Our dedicated order follow-up team keeps clients informed about production schedules, QC processes, packaging methods, and loading processes.

Adherence to Standards:

We adhere to sea transportation standards and INCOTERMS 2010 for safe and efficient product delivery.

Customized Packaging Solutions:

All products are carefully packed according to their size and weight, ensuring safe transportation.

Tailored package solutions are designed for different materials and systems.

On-site Technical Support and Training:

For clients new to our systems or seeking performance enhancements, we arrange for on-site technical experts to provide support, training, and inspections.

Our experts remain on-site until construction teams master the application methods of our formwork and scaffolding systems.

In summary, Yancheng Lianggong Formwork Co., Ltd. combines a diverse product portfolio with professional consultancy services, technical planning expertise, comprehensive support, adherence to standards, customized packaging solutions, and on-site technical support, making us the preferred partner for formwork and scaffolding solutions.

The corporate culture of Lianggong Formwork encompasses a set of profound values and far - reaching aspirations.

At the core of our corporate culture is the unwavering pursuit of excellence. We strive for perfection in every stage of our operations, from the initial design concept of our formwork products to the final delivery. Whether it's the precision of our manufacturing processes, the innovation in our product features, or the efficiency of our project execution, we set the bar high. This pursuit drives us to constantly challenge the status quo, explore new technologies, and improve our capabilities, ensuring that we are always at the forefront of the formwork industry.

Quality is the cornerstone of Lianggong Formwork. We understand that our products play a crucial role in construction projects, and thus, we spare no effort in ensuring top - notch quality. From the selection of raw materials, which are sourced from trusted suppliers and undergo rigorous quality inspections, to the implementation of strict quality control measures during production, every step is carefully monitored. Our quality assurance team is equipped with advanced testing equipment and adheres to international and domestic standards, guaranteeing that each formwork product leaving our factory meets or exceeds the highest quality benchmarks.

Serving our customers is at the heart of what we do. We believe that understanding our customers' needs is the key to providing exceptional service. Our dedicated customer service team is always ready to listen, offering comprehensive pre - sales consultations to help customers choose the most suitable formwork solutions for their projects. During the project implementation, we provide on - site technical support and guidance to ensure smooth operations. Even after the sale, we maintain close communication with customers, promptly addressing any after - sales issues and continuously improving our services based on their feedback.

Lianggong Formwork aims to be the leader in China's formwork system. We invest heavily in research and development to drive innovation in formwork technology, constantly introducing new products and solutions that are more efficient, durable, and environmentally friendly. By setting industry standards and best practices, we strive to raise the overall level of the domestic formwork industry. We also actively participate in industry conferences and standard - setting activities, sharing our expertise and experiences to contribute to the healthy development of the entire industry.

We recognize that our employees are the most valuable asset of the company. To this end, we are committed to creating a comfortable and inclusive work environment. Our modern office facilities and production workshops are designed to provide a safe and pleasant working space. We offer a wide range of amenities, including comfortable break rooms, state - of - the - art training facilities, and wellness programs. In addition, we focus on employees' career growth. We provide extensive training opportunities, both internally and externally, to help employees enhance their professional skills. We also encourage employees to take on new challenges, support their innovative ideas, and provide a clear career development path, enabling them to realize their full potential within the company.

As a responsible corporate citizen, Lianggong Formwork is committed to contributing to society. One of our important contributions is creating more job opportunities. We believe that by expanding our business and operations, we can provide stable employment for people from different backgrounds and skill levels. Whether it's in our manufacturing plants, sales and marketing departments, or research and development teams, we offer a variety of job positions, from entry - level to highly specialized ones. By doing so, we not only help individuals and families improve their living standards but also contribute to the economic development and social stability of the regions where we operate.

.webp)

All raw materials are thoroughly inspected upon arrival to ensure they meet specified standards and requirements.

Defects, dimensions, and material composition are carefully checked.

Each piece is inspected after cutting to verify accuracy in size and shape.

This ensures perfect fitment of all pieces during assembly.

Prior to mass production, the first piece produced is inspected.

This validates compliance with design specifications and quality standards, helping to identify and rectify potential issues early.

All tools and measurement equipment, such as inspection rulers, are regularly calibrated and inspected.

This maintains accuracy and reliability, ensuring precise measurements throughout production.

Fillet weld gauges are used to inspect weld beads for consistency in size and shape.

This ensures compliance with required welding standards.

Initial welds during the assembly process are carefully inspected.

Proper welding techniques and adhesion are ensured, preventing potential weak points in the structure.

After surface treatment, a series of inspections are conducted.

This includes a cross-cut inspection to assess adhesion and durability of the coating.

The cross-cut test involves making small cuts in a grid pattern on the coated surface, then applying tape to check for peeling or flaking.